Adjustable shock absorbers is an industrial hydraulic shock absorber that is maintenance-free pressure adjustable, aim at the change of moving object’s speed , adjustment and the matching of available regulator is the most appropriate buffer that with absorbing ability, formed good buffer effect. Meanwhile the adjustable shock absorbers piston rod with high hardness and imported special seals are ensuring high service life , special materials and surface treatment makes this product has good anti-corrosion performance, ensured the normal use in harsh conditions.

Features:adjustable shocks have full thread’s design is easy to install, pressure can be adjusted

Buffer body:adjustable shocks have high strength hardened steel, surface black finish

The piston rod: high hardness of stainless steel

Piston:wear-resisting for copper

Suitable for working temperature range in - 40 ℃to +80℃

Matters needing attention:

1.Pay attention to the strength of fixed plate and eccentric Angle when assembly

2.No painting in tube teeth and the axis, so as not to affect the cooling effect and leak case.

3.Keep the adjustable hydraulic damper piston rod clean, do not have iron foreign body

4.If adjustable hydraulic damper have the cushion cap product, do not unload cushion cap by self for using, this will seriously affect the service life

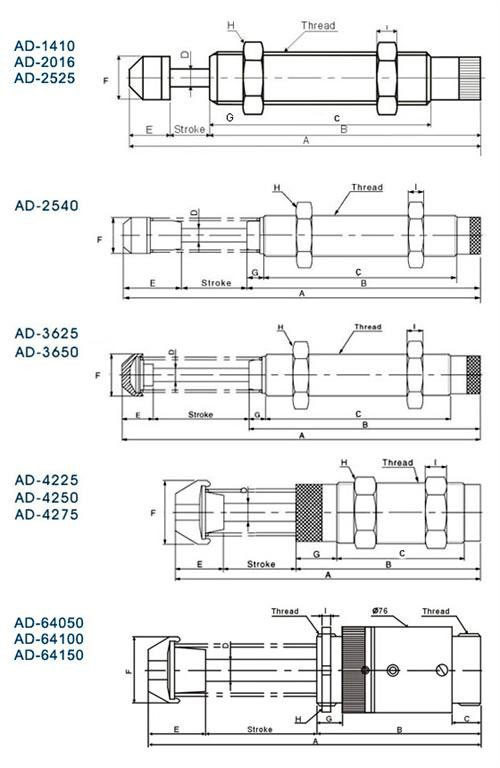

|

Model |

Thread |

Stroke(mm) |

A |

B |

C |

D |

E |

F |

H |

I |

|

AD1410 |

M14×1.5 |

10 |

103.3 |

78.3 |

67 |

4 |

14.6 |

12 |

19 |

5 |

|

AD2016 |

M20×1.5 |

16 |

134.5 |

100 |

84 |

6 |

18 |

18 |

27 |

7 |

|

AD2020 |

M20*1.5 |

20 |

154.5 |

116 |

100 |

6 |

16 |

18 |

27 |

7 |

|

AD2025 |

M20*1.5 |

25 |

159.5 |

116 |

100 |

6 |

16 |

18 |

27 |

7 |

|

AD2525 |

M25×1.5 |

25 |

161 |

116 |

101 |

8 |

19.5 |

22 |

32 |

8 |

|

Model |

Thread |

Stroke(mm) |

A |

B |

C |

D |

E |

F |

G |

H |

I |

|

AD2540 |

M25×1.5 |

40 |

218 |

132 |

115 |

8 |

36 |

22 |

10 |

32 |

10 |

|

AD3625 |

M36×1.5 |

25 |

184 |

133 |

103 |

10 |

26 |

35 |

10 |

46 |

15 |

|

AD3650 |

M36×1.5 |

50 |

247 |

171 |

134 |

10 |

26 |

35 |

17 |

46 |

15 |

|

AD4225 |

M42×1.5 |

25 |

186.9 |

127.5 |

88.5 |

12 |

33.9 |

43.7 |

29 |

49 |

15 |

|

AD4250 |

M42×1.5 |

50 |

246 |

157.3 |

118.3 |

12 |

38.2 |

43.7 |

29 |

49 |

15 |

|

AD4275 |

M42×1.5 |

75 |

301.4 |

187.8 |

148.8 |

12 |

38.2 |

43.7 |

29 |

49 |

15 |

|

AD-64050 |

UNF21/2-12 |

50 |

247.8 |

146 |

26 |

20 |

51.8 |

59 |

23 |

76.2 |

9.4 |

|

AD-64100 |

UNF21/2-12 |

100 |

347.8 |

196 |

26 |

20 |

51.8 |

59 |

23 |

76.2 |

9.4 |

|

AD-64150 |

UNF21/2-12 |

150 |

467.8 |

256 |

26 |

20 |

51.8 |

59 |

23 |

76.2 |

9.4 |

|

Model |

Stroke |

Energy Absorption(Nm)

|

Hours of Energy Absorption (Nm) |

Max Effective mass(kg) |

Max Impact Speed(m/s) |

Operating

|

Weight(g) |

||||

|

1 |

2 |

3 |

1 |

2 |

3 |

||||||

|

AD1410 |

10 |

20 |

25000 |

80 |

80 |

80 |

3 |

3 |

3 |

-40~80 |

90 |

|

AD2016 |

16 |

25 |

30000 |

200 |

200 |

200 |

3.5 |

3.5 |

3.5 |

-40~80 |

230 |

|

AD2020 |

20 |

35 |

35000 |

250 |

250 |

250 |

3.5 |

3.5 |

3.5 |

-40~80 |

250 |

|

AD2025 |

25 |

39 |

39000 |

312 |

312 |

312 |

3.5 |

3.5 |

3.5 |

-40~80 |

260 |

|

AD2525 |

25 |

85 |

70000 |

400 |

400 |

400 |

3.5 |

3.5 |

3.5 |

-40~80 |

350 |

|

AD2540 |

40 |

100 |

80000 |

700 |

700 |

700 |

3.5 |

3.5 |

3.5 |

-40~80 |

455 |

|

AD3625 |

25 |

150 |

90000 |

1400 |

1400 |

1400 |

3 |

3 |

3 |

-40~80 |

955 |

|

AD3650 |

50 |

300 |

100000 |

1400 |

1400 |

1400 |

3 |

3 |

3 |

-40~80 |

1100 |

|

AD4225 |

25 |

260 |

125000 |

3000 |

3000 |

3000 |

3.5 |

3.5 |

3.5 |

-40~80 |

1280 |

|

AD4250 |

50 |

500 |

150000 |

4000 |

4000 |

4000 |

4.5 |

4.5 |

4.5 |

-40~80 |

1495 |

|

AD4275 |

75 |

750 |

180000 |

6000 |

6000 |

6000 |

4.5 |

4.5 |

4.5 |

-40~80 |

1710 |

|

AD6450 |

50 |

12000 |

1500000 |

12727 |

12727 |

12727 |

1.5 |

1.5 |

1.5 |

-40~80 |

4115 |

|

AD64100 |

100 |

24000 |

2000000 |

18181 |

18181 |

18181 |

1.5 |

1.5 |

1.5 |

-40~80 |

5280 |

|

AD64150 |

150 |

36000 |

2500000 |

23636 |

23636 |

23636 |

1.5 |

1.5 |

1.5 |

-40~80 |

6785 |

|

|

|

|

| AD1410 | AD2016 | AD2020-N |

|

|

|

|

| AD2025 | AD2525 | AD2540 |

|

|

|

|

| AD3650 | AD3650 | AD4225 |

|

|

|

|

| AD4250 | AD4275 | AD64050 |

|

|

|

|

| AD64100 | AD64150 |

|